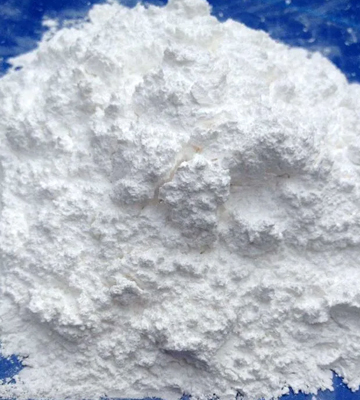

PVC

Polyvinyl chloride (PVC) resin is a robust plastic polymer synthesized from vinyl chloride monomers through polymerization processes. It is valued for its durability, chemical resistance, and diverse applications spanning construction materials to medical devices.

Plasticizer

A plasticizer is a substance added to polyvinyl chloride (PVC), to enhance its flexibility, workability, and processability. By incorporating plasticizers into the polymer matrix, the material becomes more pliable and easier to shape or mold. This modification improves

Processing Aid

Processing aids are additives used in plastics manufacturing to improve the processing characteristics of the material. They lower melt viscosity, enhancing flow and making the plastic easier to handle. This results in better mold filling, reduced production issues, and increased

Stabilizers

Stabilizers are additives crucial for preventing PVC degradation caused by heat and light exposure.

Lubricants

Lubricants in PVC formulations prevent the material from sticking to processing equipment and enhance

Impact Modifier

An impact modifier is an additive blended with PVC to improve its toughness and resistance to impact.

Fillers

Fillers are inert materials added to PVC formulations to reduce costs and improve certain properties like stiffness and electrical strength. They include calcium carbonate, talc, and other minerals.

Pigments

Pigments are colorants used to impart specific hues to PVC products. They include inorganic and organic types (such as phthalocyanines). Pigments must be compatible with PVC's chemistry

Others

Here are other chemicals we supply: 1. Foaming Agent: Creates gas upon heating, forming bubbles that reduce density and improve insulation, used in products like shoes and flooring.